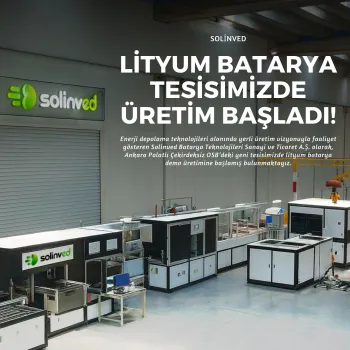

Sustainable energy use is becoming increasingly widespread with solar energy, electric vehicles, and energy storage systems. Lithium batteries are a key component of these systems. Lithium batteries are revolutionizing energy storage solutions with their high energy density, long lifespan, and low maintenance requirements. Solinved is pioneering domestic and reliable lithium battery production in Turkey with the launch of a demonstration production line at its new facility in the Polatlı Çekirdeksiz Organized Industrial Zone in Ankara.

Lithium batteries are rechargeable batteries known for their high energy density and lightweight construction. They are used to store energy in solar energy systems, electric vehicles, and industrial storage systems.

The main advantages of lithium batteries are:

Lithium battery production is a process that requires advanced technology and high precision. The basic steps are as follows:

1. Material Preparation

Lithium battery production begins with the preparation of raw materials such as lithium, cobalt, nickel, and graphite. These materials form the battery's cathode and anode structures. Solinved maximizes battery performance by using high-quality raw materials.

2. Electrode Production

Cathode and Anode Coating: Materials containing lithium, nickel, or cobalt are coated onto the electrode surfaces.

Drying and Pressing: The coated electrodes are dried and pressed to increase their density. This process increases the battery's energy density and lifespan.

3. Cell Assembly

Electrode and Separator Assembly: The cathode and anode are assembled using special separators.

Cell Encapsulation: The cell is placed in a special coating and enclosure to prevent leakage and ensure safe operation.

4. Electrolyte Filling and Activation

Electrolyte Addition: Electrolyte is added to the cell to facilitate ion transfer.

Formation Process: Performance tests are performed by subjecting the battery to a charge/discharge cycle. This step determines the battery's capacity and efficiency.

5. Testing and Quality Control

Solinved lithium batteries undergo rigorous quality control tests after production:

Lithium batteries are used in a wide variety of energy systems:

Solar Energy Systems:

By storing energy from solar panels, they enable energy use even at night or on cloudy days.

Electric Vehicles (EVs):

Lithium batteries enable electric vehicles to be lightweight and have long ranges. Solinved offers integrated solutions with EV charging systems.

Agricultural Irrigation Systems:

Lithium batteries can be used in irrigation pumps to provide energy independence, enabling uninterrupted irrigation.

Industrial Energy Storage:

Used to store energy in commercial facilities, reduce energy costs, and balance peak-time loads.

Home Storage Systems:

Ideal for storing solar-generated electricity and enabling nighttime use.

Solinved Battery Technologies Industry and Trade Inc. has begun demonstration lithium battery production at its 2,500 m² facility, located directly next to the solar panel factory.

With this facility, Solinved not only produces battery enclosures but also container-type energy storage systems, electric vehicle charging stations, solar inverter systems, and driver boards for solar drives.

With the increasing use of solar energy and electric vehicles, lithium battery production is a rapidly growing sector. Solinved supports the energy transition with high-performance and safe battery production. The efficiency and durability of lithium batteries make renewable energy systems more sustainable and economical.

1. How long do lithium batteries last?

Solinved lithium batteries typically offer high performance for 10–15 years.

2. In what systems can lithium batteries be used?

They can be used in solar energy systems, electric vehicles, agricultural irrigation, and industrial energy storage systems.

3. Do lithium batteries require maintenance?

Maintenance is minimal; periodic inspection and cleaning are often sufficient.

4. Are lithium batteries safe?

Solinved lithium batteries are designed to resist the risks of short circuits, overheating, and leakage.

5. How is lithium battery integration with solar energy performed?

DC energy generated from solar panels is directed to the battery and stored using Solinved inverters and charge controllers.

6. What is the production capacity of Solinved lithium batteries?

We can produce 600 51.2V 100Ah (5kWh) batteries daily, with an annual production capacity of 1 GWh.

7. What is the battery lifespan?

They offer high performance for 10–15 years.

8. Is integration with an energy storage system possible?

Yes, Solinved batteries can be integrated with solar panels, solar inverters, and EV charging systems.