Driver Dashboards

-

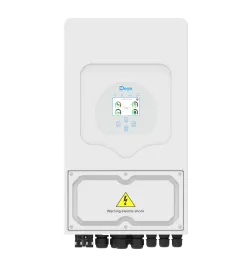

Driver Dashboards Solinved DKP-Type1 Panel ( 1.5 KW - 5.5 KW )220,00 $6.332,15 ₺ + KDV143,00 $ + KDV

Driver Dashboards Solinved DKP-Type1 Panel ( 1.5 KW - 5.5 KW )220,00 $6.332,15 ₺ + KDV143,00 $ + KDV -

Driver Dashboards Solinved DKP-Type2 Panel ( 7.5 KW - 15 KW )250,00 $7.195,63 ₺ + KDV162,50 $ + KDV

Driver Dashboards Solinved DKP-Type2 Panel ( 7.5 KW - 15 KW )250,00 $7.195,63 ₺ + KDV162,50 $ + KDV -

Driver Dashboards Solinved DKP-Type3 Panel ( 18.5 KW - 22 KW )470,00 $13.527,78 ₺ + KDV305,50 $ + KDV

Driver Dashboards Solinved DKP-Type3 Panel ( 18.5 KW - 22 KW )470,00 $13.527,78 ₺ + KDV305,50 $ + KDV -

Driver Dashboards Solinved DKP-Type4 Panel ( 30 KW - 37 KW )600,00 $17.269,51 ₺ + KDV390,00 $ + KDV

Driver Dashboards Solinved DKP-Type4 Panel ( 30 KW - 37 KW )600,00 $17.269,51 ₺ + KDV390,00 $ + KDV -

Driver Dashboards Solinved DKP-Type5 Panel ( 45KW - 55 KW )800,00 $23.026,02 ₺ + KDV520,00 $ + KDV

Driver Dashboards Solinved DKP-Type5 Panel ( 45KW - 55 KW )800,00 $23.026,02 ₺ + KDV520,00 $ + KDV -

Driver Dashboards Solinved DKP-Type6 Panel ( 75KW - 110 KW )1.300,00 $37.417,28 ₺ + KDV845,00 $ + KDV

Driver Dashboards Solinved DKP-Type6 Panel ( 75KW - 110 KW )1.300,00 $37.417,28 ₺ + KDV845,00 $ + KDV

Drive panels are essential components used to control industrial motors. These panels control motor parameters such as speed, torque, and direction, playing a critical role in improving energy efficiency and ensuring smooth system operation.

Components and Functions of Drive Panels

A drive panel consists of several components that work together to ensure motors run efficiently and reliably. Key components include:

- Variable Frequency Drives (VFDs): These drives adjust motor speed and torque, providing the necessary power to the motor.

- Power Supply and Distribution Components: The panel manages the flow of electrical energy required for the operation of the drives and other components.

- Protection Equipment: Circuit breakers, fuses, and thermal relays protect the panel from overload and short circuit situations, ensuring the motor’s safe operation.

Energy Efficiency and Savings

Drive panels improve energy efficiency by ensuring that motors only consume the power they need. Specifically, Variable Frequency Drives (VFDs) optimize energy consumption by adjusting motor speed accordingly, reducing energy usage and lowering operational costs.

High Performance and Motor Protection

Drive panels ensure longer motor life by providing protection and smooth operation. Features like soft start and stop capabilities prevent sudden power surges, reducing mechanical wear and electrical stress.

- Soft Start and Stop: Motors are protected from abrupt power fluctuations, which helps them last longer.

- Protection Systems: Protection features in drive panels guard motors against overload and short circuits, enhancing reliability.

Industrial Applications and Usage Areas

Drive panels are widely used across various industrial sectors. Some common applications include:

- Pump Systems: Control motor speeds in water supply, drainage, and irrigation systems.

- HVAC Systems: Regulate motor speed in heating, ventilation, and air conditioning systems for efficiency.

- Conveyor and Material Handling Systems: Manage motor control in production lines.

- Energy Generation Facilities: Optimize motor operation in generators and other equipment to improve energy efficiency.

Considerations When Choosing a Drive Panel

When selecting a drive panel, several factors should be considered:

- Power and Voltage Compatibility: Ensure the drive panel is compatible with the motor’s power and voltage requirements.

- Protection Features: The panel should offer protection against overloads, short circuits, and overheating.

- Integration with Other Systems: Drive panels should be compatible with other automation systems for optimal integration.

Drive panels are vital in improving energy efficiency, protecting motors, and optimizing energy consumption in industrial motor control systems. The right choice of drive panel ensures long-lasting, efficient operation. Regular maintenance and proper component selection will maximize system performance.